|

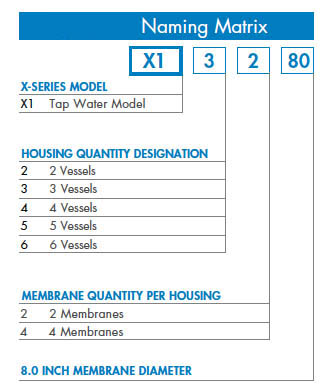

INDUSTRIAL BREW

Microbrew X1-Series Reverse Osmosis Systems |

The Microbrew X1-Series 8” Industrial Reverse Osmosis Systems are designed as a cost-effective solution to

the growing demand in industrial water treatment

of tap water

and well water for a multitude of

applications in food & beverage, pharmaceutical,

healthcare, microelectronics, power, chemicals,

and agriculture.

With models ranging from 25 to 125 gallons per

minute (30,000 to 180,000 gallons per day), the

smart, clean utilitarian industrial design of the

X1-Series allows for convenient installation,

user-friendly operation, and ease of maintenance.

These skid-mounted, package systems are

pre-plumbed and pre-wired on a powder-coated

steel frame complete with a pre programmed

computer, TDS probes, and panel-mounted

pressure and "ow instrumentation allowing for

straight forward system monitoring and control. |

|

|

Featuring robust components selected for enhanced performance, the X1-Series includes a stainless steel vertical multistage

pump, stainless steel cartridge filter housing, stainless steel valving, and FRP pressure vessels with stainless steel side ports.

The larger models also include VFD motor control of the pump and a motorized feed valve.

The X1-Series systems utilize energy-efficient ultra low energy membranes with 10% greater membrane surface area than

standard 8” RO elements thus producing more pure water. |

| Standard Features |

- S-150 Pre-programmed Computer Controller*

- S-200 Pre-programmed Computer Controller w/VFD**

- Permeate and Concentrate Rotometers*

- Permeate and Concentrate Digital Paddle Wheels*

- Pre- and Post-Filter Pressure Gauges

- Pump Pressure and Concentrate Pressure Gauges

- Feed and Permeate TDS

- 8” Ultra Low Energy Elements with 440 SF Membrane

- 300 psig FRP vessels w/Stainless Steel Side Ports

- Multi-Cartridge Stainless Steel Filter Housing

- 5-Micron Sediment Cartridge Filters

- Vertical Stainless Steel Multistage Pump

|

- Composite Feed Solenoid Valve*

- Motorized Feed Valve**

- Stainless Steel Globe Throttling Valves

- Low and High Pressure Shut-Off Switches

- Powder-Coated Carbon Steel Frame

- Sch80 PVC Piping

- Permeate Sample Ports

- Chemical Feed Port

- Chemical Feed Power Outlet

- Permeate Sample Ports

- Voltage: 220VAC 3PH 60 HZ

|

|

| |

| Optional Features |

- S-200 Computer Controller***

- VFD***

- Programmable Logic Controller (PLC) w/Touch Screen

- Permeate and Concentrate Digital Paddle Wheels***

- Motorized Feed Valve***

- Concentrate Recycle Loop w/Flow Meter

|

- Permeate Divert

- Permeate Flush

- pH and/or ORP Sensor

- Chemical Feed System

- Clean-In-Place Skid-Mounted System

- Clean-in-Place (CIP) Ports

|

*Standard on Models X1-2280, X1-3280, X1-4280, X1-5280

**Standard on Models X1-3480, X1-4480, X1-5480, X1-6480

***Option available for Models X1-2280, X1-3280, X1-4280, X1-5280. Standard on larger models.

|

|

|

| Microbrew X1-Series Reverse Osmosis Systems |

|

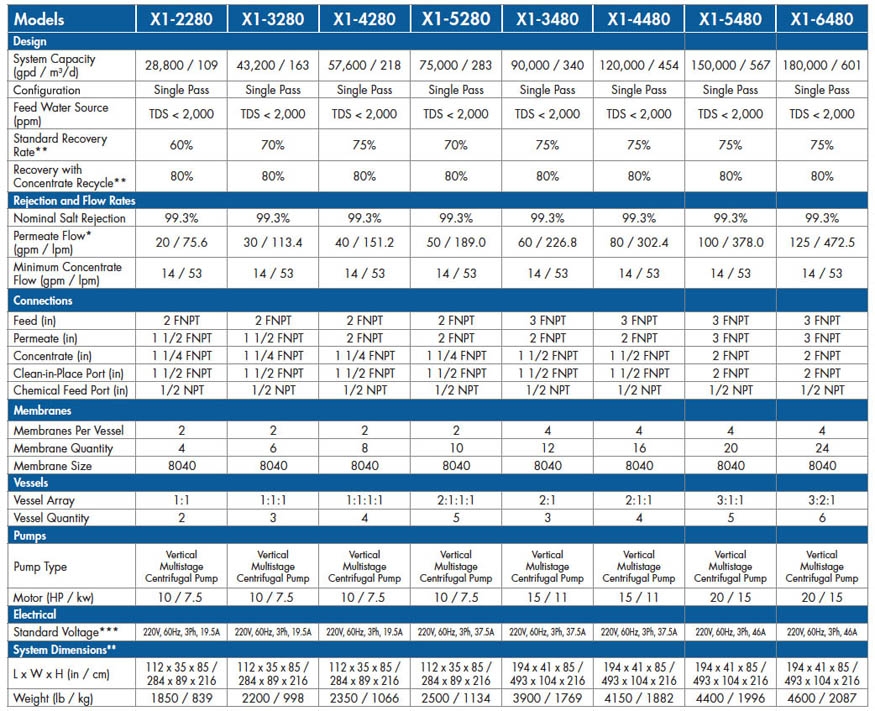

*Product flow and recovery rates are based on feedwater conditions of 2000 ppm TDS at 77oF. Treatment ability of the RO system is dependent on feed water quality.

Higher TDS and/or lower temperatures will reduce product "ow. A Microbrew Applications Engineer can rate the units for these other feed water conditions.

**A concentrate recycle loop is available as an option to increase recovery to 75 to 80% (if suitable to feed water conditions).

***Other voltage options are available. |

| |

| Operating Limits |

| Design Temperature (°F / °C) |

77 / 25 |

Maximum Free Chlorine (ppm) |

0 |

| Maximum Feed Temperature (°F / °C) |

85 / 29 |

Design TDS (ppm) |

2,000 |

| Minimum Feed Temperature (°F / °C) ^ |

50 / 10 |

Maximum TDS (ppm) ^ |

3,000 |

| Maximum Ambient Temperature (°F / °C) |

120 / 48.9 |

Maximum Hardness (gpg) ^^^ |

0 |

| Minimum Ambient Temperature (°F / °C) |

40 / 4.4 |

Maximum pH - Continuous |

11 |

| Maximum Pump Inlet Pressure (psi / bar) |

85 / 5.9 |

Minimum pH - Continuous |

3 |

| Minimum Pump Inlet Pressure (psi / bar) |

45 / 3.1 |

Maximum pH - Cleaning 30 Min. |

12 |

| Maximum Pump Pressure (psi / bar) |

230 / 16 |

Minimum pH - Cleaning 30 Min. |

2 |

| Maximum SDI Rating (SDI) ^^ |

< 3 |

Maximum Turbidity (NTU) ^^ |

Up to 1 |

| |

^Product flow and recovery rates are based on feedwater conditions of 2000 ppm TDS at 77oF. Treatment ability of the RO system is dependent on feed water quality.

Higher TDS and/or lower temperatures will reduce product flow. A Microbrew Applications Engineer can rate the units for these other feed water conditions.

^^Appropriate filtration must be installed in order to prevent premature membrane fouling.

^^^Scale prevention measures must be taken to prolong membrane life. |

|

|

|